|

When the user uses the forecasting screen and select the weeks out we will display all items with weeks out value less than or equal the value selected.

The following is used to calculate Weeks Out value:

- Lead Time (LT): Lead time can be user defined, or automatically calculated during a nightly job. The lead time represents how quickly the user receives the POs from the vendors of the items ordered.

- The lead time is calculated as the average of the days between placing an order to a vendor and actually receiving the item.

- The average is calculated from all uncancelled POs for the past year.

- Mean Daily Demand (MDD): Is the average of how many items have been ordered in a certain period.

- P = 60, unless the calculated lead time is over 60 days; then, P = lead time.

- Mean Daily Demand (MDD) = Total Quantity Ordered For This Item / P

- Standard Deviation of Demand (σ Demand): It is the standard deviation of the quantities ordered daily within the same period used to calculate the Mean Daily Demand.

- Safety Stock:

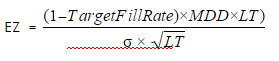

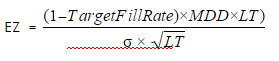

- Safety Stock =

Where Z is a statistical standard-deviation multiplier representing a target service level.

We use the output of this formula to search this table for the nearest EZ value and return the corresponding Z value:

-

- Reorder Point (ROP): Reorder point is a value that either is set by the user or calculated by the system in a nightly job.

- Finally the Weeks Out value is calculated as the following

- It will be set to zero if the available quantity < Reorder point of that item or the Mean Daily Demand is zero.

- Otherwise it will be set to the integer less than or equal to the result of

- ((Available - ReorderPoint) / MeanDailyDemand) / 7

|